-

article · 2026Year8Moon8Day

选择 Opentrons Flex 的 7 大理由

Read More -

article · 2026Year4Moon8Day

Opentrons Flex 实用操作技巧:新手必读

Read More -

article · 2026Year43Moon7Day

高通量 NGS 建库流程中的关键步骤与 Opentrons Flex 支持

Read More

Scope: The purpose of this Standard Operating Procedure (SOP) is to describe methods for verifying and inspecting pipettes to ensure that pipettes are dispensed with the expected accuracy. This determines the difference between the dispensed volume and the selected volume.

Materials: For a quick check, the following materials are required: pipette, pipette tips (manufacturer recommendation), appropriate calibrated laboratory balance, evaporation trap (or suitable weighing container), test liquid ( deionized water), thermometer, pressure gauge, gloves, worksheet, or software.

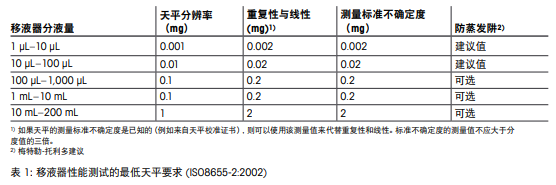

The ISO 8655 standard has very strict minimum requirements for the weighing equipment used, which for practical purposes depend on the nominal capacity of the pipette being tested.

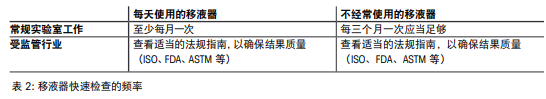

Frequency of quick checks, test volume and number of repetitions The higher the risk of failure, the more frequently the pipettes should be quick checked.

Pipettes should be inspected at least once completely (nominal volume). Depending on the criteria implemented, a larger number (10%, 50%) of testing is required.

A standard pipette quick check procedure typically follows the following 10 steps for a quick check:

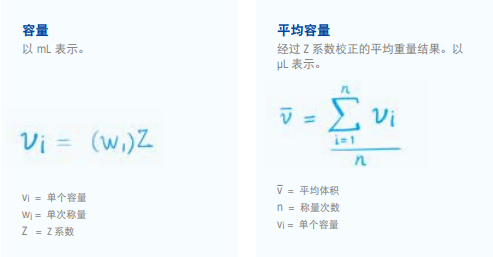

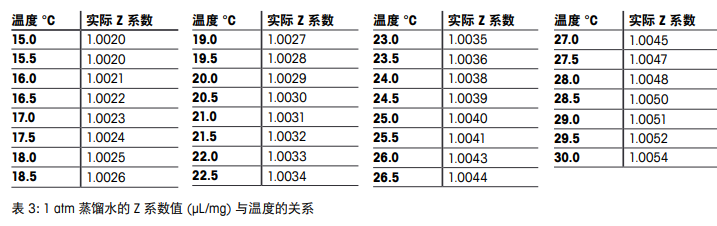

Formulas, Z-Factors, and Calculations Formulas for calculating the average volume, accuracy (mean error), and precision (standard deviation) of a pipette:

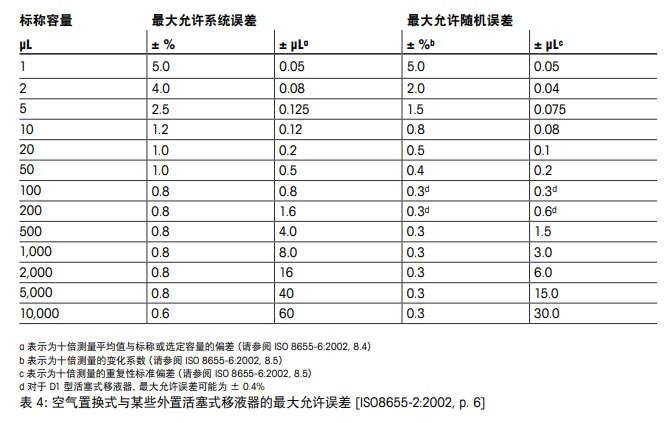

Tolerance, maximum allowable error (ISO 8655) ISO 8655 clearly defines maximum error limits for piston-operated pipettes. This standard describes the maximum allowable systematic error and the maximum allowable random error limits for devices with specific volumes in the range 1–10,000 μL. These errors are doubled for multichannel pipettes. Most pipette manufacturers specify tolerances well below these limits, but when making low-volume measurements, meeting ISO8655 tolerances can become a challenge for many service providers.

If your results do not match your pipette's specifications, your pipette needs maintenance or calibration.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인