-

article · 2026Year57Moon4Day

Opentrons Flex vs 其他自动化 NGS 工作站对比评测

Read More -

article · 2026Year52Moon4Day

如何通过 Opentrons Protocol Library 运行 NGS 流程?

Read More -

article · 2026Year28Moon3Day

Opentrons Flex 的节省成本优势与投资回报分析

Read More

Pipette plunger stuck is a common problem, and its causes are various. It may be caused by incorrect tightening of the pipette head, over-tightening, over-tightening of the holder, loose pulleys, or tip damage due to long-term use. Wear, or adhesion due to excessive liquid impurities. In response to this frequent failure, the following provides a series of refined maintenance suggestions:

1. Careful inspection and timely adjustment 1. Verify the tightening status of the pipette head: Please ensure that the pipette head is tightly screwed to prevent the plunger from getting stuck due to looseness. If it is found that the head is difficult to open due to over-tightening, it is recommended to use a suitable tool to gently loosen it to avoid damage to the components. 2. Assess the status of the bracket and pulley: carefully check the tightness of the pipette bracket and adjust it appropriately to ensure that it is appropriately tight. Check the pulley carefully to ensure that it is stable and not loose. If there is any abnormality, it should be replaced or repaired in time.

2. Deep cleaning and reasonable lubrication 1. Implement disassembly and thorough cleaning: follow the disassembly process of the pipette and carefully disassemble the plunger and related parts. Use special cleaners (such as acetone) and cotton swabs to deeply clean the plunger and components to completely remove surface dirt and impurities. 2. Apply an appropriate amount of lubricant: After cleaning, apply a layer of special lubricant evenly on the surface of the plunger and components to ensure smooth movement of the plunger.

3. Component replacement and comprehensive inspection 1. Replace worn tips: Regularly check the wear of the tip. Once obvious wear or deformation is found, replace it immediately to avoid affecting pipetting accuracy. 2. Comprehensive inspection and replacement of damaged parts: If the plunger or other key parts cannot be repaired due to wear and tear, original parts should be purchased and replaced in time.

4. Professional maintenance service consultation 1. Contact the professional maintenance team: If personal maintenance fails, it is recommended to contact the pipette manufacturer or the professional maintenance team for professional maintenance advice and services. 2. Follow safety regulations: During the maintenance process, be sure to follow the maintenance guidelines and safe operating procedures provided by the manufacturer to ensure the safety and effectiveness of the operation.

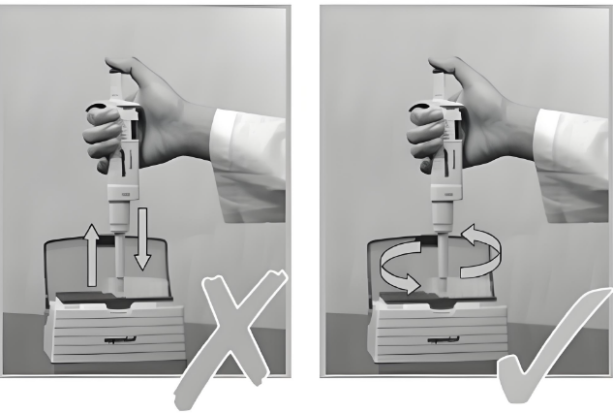

5. Implementation of preventive measures 1. Establish a regular maintenance system: Develop a regular maintenance plan for the pipette to ensure that each component is always in the best condition. 2. Correct use and maintenance: When using the pipette, please follow the correct operating steps to avoid component damage or jamming caused by improper use.

Repair methods for a stuck pipette plunger include inspection and adjustment, cleaning and lubrication, replacing damaged parts, and seeking professional repair services. During the maintenance process, be sure to follow relevant guidelines and operating procedures to ensure maintenance effectiveness and safety. At the same time, through regular maintenance and correct use of pipettes, problems such as plunger jamming can be effectively prevented.

Related reading recommendations

Pipette White Paper: 4-in-1 Centrifuge Tube Rack

Handling robot instrument service overview

Pippet White Paper: Thermal Cycling Module

Micropipette verification procedures

Common causes of pipette leakage and measures to avoid leakage

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인