-

article · 2026Year2Moon5Day

Opentrons Flex 高通量 NGS 工作站安装与调试全流程

Read More -

article · 2026Year57Moon5Day

实验室如何利用 Opentrons Flex 实现高质量数据输出

Read More -

article · 2026Year57Moon4Day

Opentrons Flex vs 其他自动化 NGS 工作站对比评测

Read More

The pipetting operation steps of the pipetting robot mainly include six steps: tip installation, volume setting, pre-washing the tip, pipetting, draining and removing the tip.

1. Core parameters

Origin Category: Domestic

Number of plates: 11 SBS well plate

Pipetting accuracy: 1uL

Pipetting range: 1-1000 uL

Sample throughput (pieces): 96 pieces

Instrument size: 630570660 mm

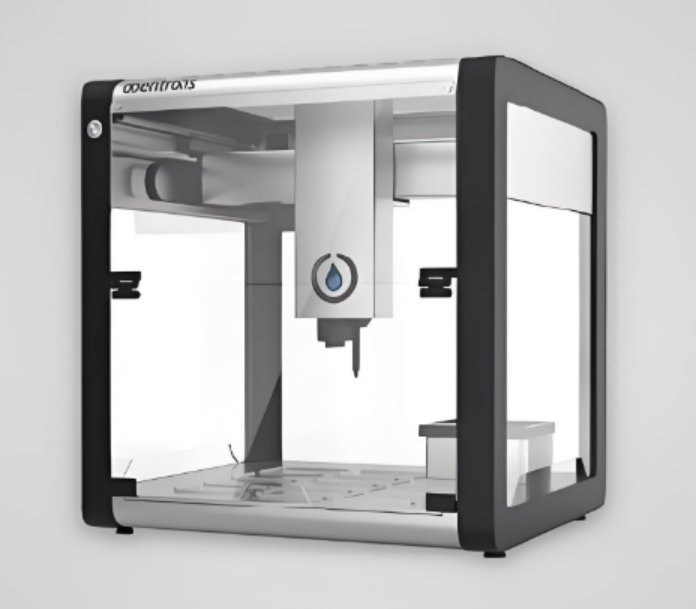

open TR ONS robot 0T-2

The automated pipetting robot OT-2 performs liquid handling in an automated manner and is suitable for research in genomics, proteomics, cell-based detection, biochemical analysis, drug research and development, etc.

Can be equipped with both single-channel and 8-channel wave shifters and 11 plate positions. Compatible with SBS standard experimental equipment. Throughput: can fill a 96-well plate in 22 seconds at the fastest.

2. Operation steps

1>Suction head installation: The correct installation method is called the rotation installation method. Insert the top of the white sleeve into the tip, press gently and at the same time, rotate 180 degrees counterclockwise. Be careful not to use excessive force to avoid damage to the pipette.

2>Capacity setting: Capacity setting is divided into two steps. The first is to quickly adjust the capacity value to close to the expected value through the discharge button. The second is to turn the pipette sideways, place it horizontally in front of your eyes, by adjusting Slowly adjust the wheel to the exact value to avoid visual errors.

3>Prewash the tip: For newly installed tips or after the capacity value is increased, the liquid to be transferred should be sucked and discharged two to three times to ensure that a homogeneous liquid film is formed on the inner wall of the tip, improvement Pipetting accuracy.

4> Pipetting: There are two main methods. Forward pipetting is suitable for large volumes, aqueous solutions, etc., Pre-rinsing of the tip is required; Reverse pipetting is suitable for special liquids or for accuracy and precision. For particularly demanding applications, improve results by aspirating the set volume plus additional volume.

5>Drainage: After pipetting, wait for 1-2 seconds, continue to press the button to the second stop point, ensure that the liquid in the tip is completely drained.

6>Remove the tip: After pipetting, adjust the pipetting capacity back to the maximum range, and press the tip ejection button to the bottom to remove the tip.

The OT-2 automated pipetting station is an efficient and precise laboratory equipment that can bring great convenience and benefits to laboratory work. Following these steps ensures accurate and efficient pipetting operations. Its automated pipetting operations, high-precision pipetting capabilities, and fast, stable, and reliable features make laboratory work more efficient and accurate.

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인