-

article · 2026Year3Moon2Day

Opentrons Flex 属于什么类型的自动化平台?

Read More -

article · 2026Year17Moon28Day

Opentrons Flex 适合什么实验?

Read More -

article · 2026Year30Moon26Day

Opentrons Flex功能有哪些?

Read More

Fully automatic pipetting workstations are becoming more and more widely used in ELISA (enzyme-linked immunosorbent assay) detection, which can greatly improve the accuracy and work efficiency of experiments. However, there are some precautions to pay special attention to when using a fully automatic pipetting workstation for ELISA testing. Only by following these operating specifications can you ensure the accuracy of the test results and avoid common operating errors.

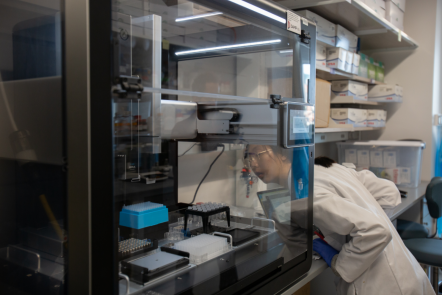

Full automatic pipetting workstation

1. Ensure the accurate calibration of the equipmentThe accuracy of the fully automatic pipetting workstation directly affects the results of ELISA detection. Therefore, before starting the experiment, it is necessary to ensure that the equipment has been accurately calibrated. Check the accuracy of the pipetting system regularly, especially after prolonged use. If there is any inaccuracy in the equipment, maintenance or recalibration should be carried out in time to avoid affecting the experimental results.

2. Select the right pipette and pipe According to the reagent dose and experimental needs of ELISA, it is crucial to choose the right pipette and pipe of the appropriate specifications. If an inappropriate needle or pipe is used, it may cause incomplete liquid transfer of samples and reagents, which will affect the sensitivity and accuracy of the detection. Therefore, when setting up a fully automatic pipetting workstation, be sure to confirm that the selected accessories match the experimental requirements.

3. Pretreatment of reagents and samplesIn ELISA detection, pretreatment of reagents and samples is very important. Improper sample pretreatment may cause the reagent to fail to react effectively, or the sample components are destroyed, thereby affecting the detection results. Therefore, before performing the fully automatic pipetting workstation operation, ensure that all samples and reagents have been processed according to the prescribed procedures to avoid sample contamination or reagent degradation.

4. Accurate control of pipetting volume Accurate control of pipetting volume is an important part of ELISA experiments. Although a fully automatic pipetting workstation can provide efficient pipetting operations, if the pipetting volume is not accurately adjusted during the setting process, the result may be deviated. Therefore, when setting experimental parameters, pay special attention to the accuracy of each parameter, avoid too much or too little reagents, and ensure the stability of the experiment.

5. Temperature controlELISA experiments have strict requirements on temperature, especially during the antigen-antibody reaction. The temperature control system of a fully automatic pipetting workstation needs to be adjusted to the appropriate temperature range according to experimental requirements. Temperatures that are too high or too low may affect the detection results. It is recommended to use temperature control function during the experiment to ensure consistency of the experimental environment.

6. Regular maintenance and cleaningA fully automatic pipetting workstation will accumulate certain reagent residues or sample stains during use. If not cleaned in time, it may affect the accuracy of the next experiment. Regularly clean the pipes, needles, reagent tanks and other parts of the equipment to ensure that the equipment is free of pollution and ensure the reliability of subsequent experimental results. In addition, regularly check the functions of the equipment to promptly discover potential problems and avoid affecting the experimental process.

7. Pay attention to the training of operatorsWhen operating a fully automatic pipetting workstation, operators must undergo professional training. Understanding the basic operating principles, setup procedures and troubleshooting methods of the equipment can greatly improve the success rate and efficiency of the experiment. Operators should be proficient in various functions and abide by the safe operating specifications for the use of the equipment to avoid experimental failure or equipment damage caused by improper operation.

8. Data recording and monitoringThe fully automatic pipetting workstation can automatically record various data during the experiment, including reagent dosage, sample processing status and temperature. Operators should monitor the progress of the experiment in real time to ensure that each step is completed as specified. At the same time, recording the data intact can help analyze experimental results, discover potential problems in a timely manner, and optimize the experimental process.

The application of fully automatic pipetting workstations in ELISA inspection greatly improves the degree of automation and accuracy of detection, but also requires high operation of the equipment. To ensure the reliability of experimental results, operators need to pay attention to equipment calibration, pipetting volume control, reagent treatment, temperature regulation and other aspects. Through regular maintenance and cleaning, professional personnel training and detailed data monitoring, errors during the experiment can be effectively avoided and the accuracy and efficiency of the experiment can be improved. Only by fully mastering and following these precautions can fully enable the fully automatic pipetting workstation to play the greatest role in ELISA inspection and ensure the high quality and efficiency of the test results.

Related reading recommendations

Use Opentrons for COVID-19 testing

OT-2 Liquid Treatment Robot Safety and Regulatory Compliance Information

8 laboratory automation complaints PI error

Opentrons Flex nucleic acid extraction workstation flexible garbage trough

How to connect to other devices in Flex magnetoglobin purification workstation

How to clean the glass suction head of the fully automatic pipetting workstation

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인