-

article · 2026Year3Moon2Day

Opentrons Flex 属于什么类型的自动化平台?

Read More -

article · 2026Year17Moon28Day

Opentrons Flex 适合什么实验?

Read More -

article · 2026Year30Moon26Day

Opentrons Flex功能有哪些?

Read More

In the precision palace of life science research, the fully automatic pipetting workstation has become an indispensable assistant in the laboratory with its unparalleled accuracy and efficiency. However, the performance of even the most cutting-edge technical equipment cannot be achieved without careful maintenance of every detail. As one of the core components of a fully automatic pipetting workstation, the cleanliness of glass tips is directly related to the reliability of experimental data and the accuracy of experimental results. Therefore, mastering the correct method of cleaning glass tips is crucial to ensure the success of the experiment.

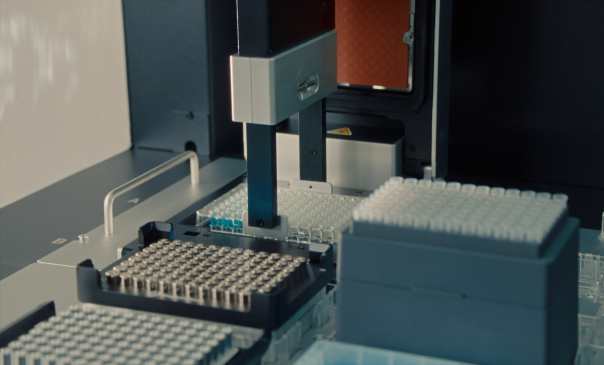

Fully automatic pipetting workstation

1. Manual cleaning 1. Disassemble the tip: First, remove the glass tip that needs to be cleaned from the pipetting workstation. 2. Soaking and rinsing: Soak the disassembled glass tip in an appropriate cleaning agent, such as special pipette cleaning solution, alcohol or sodium hypochlorite. The choice of cleaning agent should be determined based on the specific requirements of the experiment and the properties of the liquid. After soaking for a period of time, rinse the tip with distilled or deionized water to remove residual cleaning agent. 3. Drying and storage: Place the rinsed glass tips on a clean paper towel or a special tip rack to dry naturally, or use a hair dryer and other tools to blow dry. After drying, store the tips in a dedicated tip box to avoid dust and contamination.

2. Automated cleaning With the development of science and technology, there are now fully automated pipetting workstation cleaning equipment, such as fully automatic ultrasonic tip cleaning machines. This type of equipment cleans and sterilizes the suction tips through ultrasonic waves, ultraviolet light, and blowing. The cleaning efficiency is higher and the cleanliness and sterility of the suction tips can be ensured. 1. Use a cleaning machine: Place the glass tips that need to be cleaned on the tip tray of the cleaning machine. According to the operating instructions of the cleaning machine, select appropriate cleaning procedures and reagents (such as cleaning fluid, alcohol, sodium hypochlorite, etc.). Start the cleaning machine and wait for the cleaning process to complete. 2. Follow-up processing: After cleaning is completed, take out the suction head from the cleaning machine and perform necessary drying and storage.

3. Precautions 1. Avoid cross-contamination: During the cleaning process, ensure the sterility of cleaning agents, distilled water, suction heads and other tools to avoid cross-contamination. 2. Replace the cleaning agent regularly: The cleaning agent may become invalid or contaminated after being used for a period of time, so it is necessary to replace the cleaning agent regularly with new ones. 3. Follow the operating specifications: During the cleaning process, follow the operating specifications of the pipetting workstation and cleaning machine to ensure cleaning effect and safety.

Cleaning of the glass tips of the fully automatic pipetting workstation is an indispensable part of the experimental process, which is directly related to the accuracy and reliability of the experimental results. Through manual cleaning or the use of advanced automated cleaning equipment, combined with appropriate cleaning agents and standardized operating procedures, we can effectively remove residues on the tip and restore its original cleanliness and performance.

Related reading recommendations

OT-2 Declaration of Conformity

9 COVID-19 testing resources for life science researchers

Application of fully automatic pipetting workstation in cell culture

3 ways automation can lead to better biological laboratory results

The experienced service team and strong production support team provide customers with worry-free order services.

简体中文

繁體中文

English

日本語

한국인